SEMICONDUCTOR VERTEX DETECTORS IN PARTICLE PHYSICS

In recent decades, microelectronics has been intensively introduced into nuclear electronics to meet the increasing requirements for nuclear electronics. In experimental studies in the field of high and ultrahigh energy physics, multichannel silicon detectors of charged particles and their associated electronics for reading and processing information based on modern semiconductor devices, which are structurally made in the form of standard modules, are widely used.

Usage of typical detector modules solves the problems of minimizing the mass of material in the detection volume, simplifying and increasing the productivity of assembly processes while maintaining high density and high degree of assembly reliability in creating new generation of hybrid microcircuits and interconnecting cables. Including on basis of new, more advanced designs and technologies for their manufacture using multilayer flexible-rigid boards and flexible connecting cables.

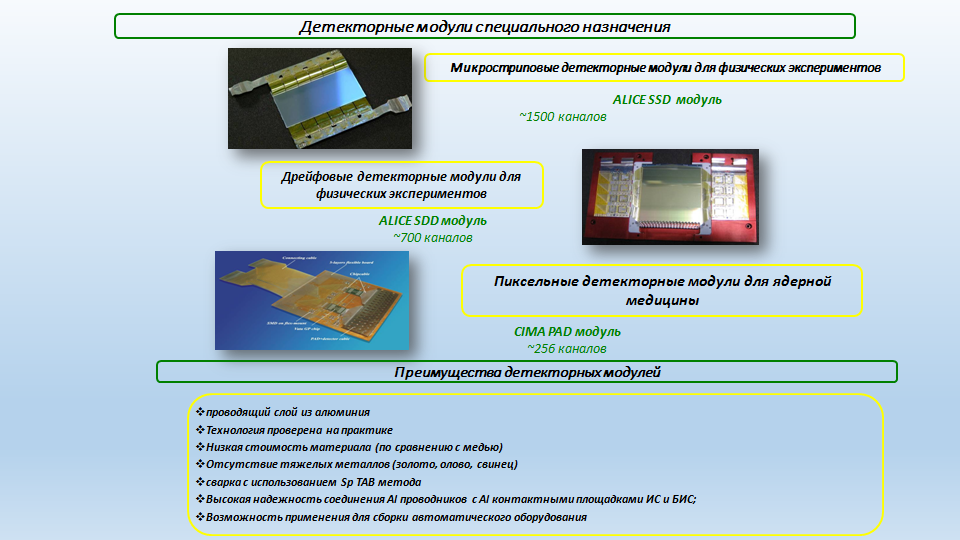

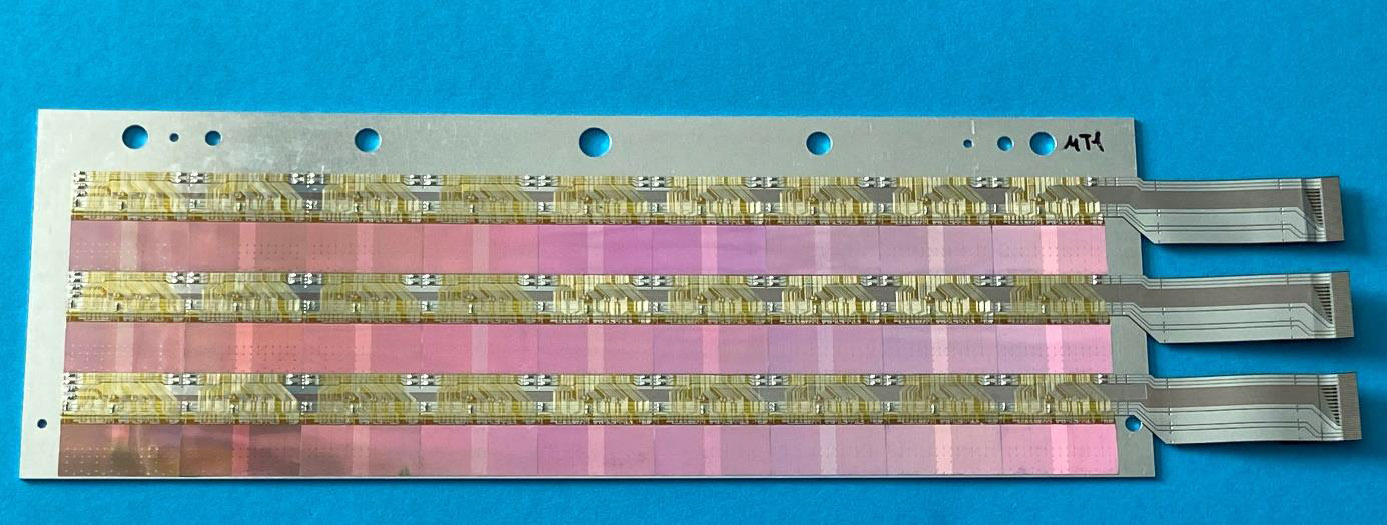

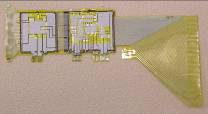

LLC «RPE «LTU» is actively developing and verifying effective approaches to creation of modern innovative design and technological solutions and manufacturing technologies for advanced microstrip, drift and matrix pixel detector modules on flexible adhesiveless aluminum – polyimide interconnection boards and cables using automated ultrasonic welding processes and COF assembly technology. Our unparalleled innovative pixel array detector module solutions, based on new generation of silicon pixel sensors, are being used to create new and upgrade existing detector systems for high energy physics experiments .

DEVELOPMENT AND MANUFACTURE OF DETECTOR MODULES

- 2009 р. – 2015 р. – R&D “Research of design and technological solutions, development, manufacture and supply of mock-ups of components and detector modules for the CBM experiment.”

- 2016 р. – R&D “Manufacturing and supply of CBM demonstrators and components for demonstrators”.

- 2017 р. – 2019 р. – R&D “Development, research and supply of multilayer flexible printed circuit boards of power cables for the ALICE ITS2 project.”

- 2018 р. – 2019 р. – R&D “Development, research and supply of multilayer flexible printed circuit boards of matching cables for the ALICE ITS2 project.”

- 2018 р. – 2021 р. – R&D “Development, manufacture and supply of flexible printed circuit boards and demonstrators for the Mu3e experiment”.

- 2019 р. – 2021 р. – R&D “Development and research of sensitive layers for the FoCal project”.

- 2020 р. – R&D “Development and study of sensitive layers based on curved sensors and SpTAB connection technology for the ALICE ITS3 project”.

- 2021 р. – R&D “Development, manufacture and supply of flexible printed circuit boards and demonstrators for the STRASSE project”.

MAIN RESULTS OF DEVELOPMENTS:

1 MATERIALS FOR FLEXIBLE CABLES AND BOARDS

2 LAYOUTS AND PROTOTYPES OF DETECTOR MODULES COMPONENTS

3 LAYOUTS AND COMPONENT DEMONSTRATORS OF DETECTOR MODULES

4 DETECTOR MODULES FOR PHYSICS EXPERIMENTS

Proposed and developed by LLC «RPE «LTU» innovative technical solutions make it possible to create such methods for manufacture of adhesiveless flexible lacquer-foil aluminum – polyimide layered materials that provide the use of simpler, low-cost and reproducible technologies for manufacture of layered materials with required geometric dimensions of wide range of used aluminum foils and polyimide layers (thickness of polyimide layers from 10 µm to 50 µm, thickness of aluminum layers from 15 µm to 100 µm) and operating in temperature range from minus 200°С up to plus 250°С (Patent of Ukraine for a utility model №. 119126 from 11.09.2017 “Method of manufacturing flexible laminate for products based on foil”).

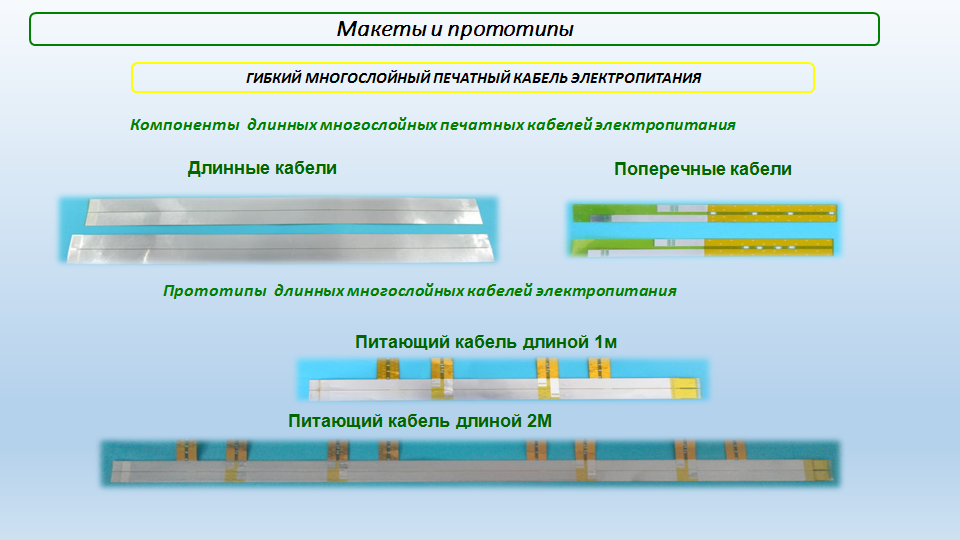

Proposed and developed by LLC «RPE «LTU» innovative technical solutions for aluminum-polyimide flexible multilayer printed power cables (Patent of Ukraine for utility model №. 142206 from 25.05.2020 “Flexible multilayer printed power cable”) make it possible to increase the resistance of power cables to mechanical stress, reduce deformation caused by temperature changes. Increase the radiation resistance and radiation length of the cable. Eliminate corrosion of welded joints, reduce the degradation of electrical characteristics, increase reliability in operation. Simplify the technology of mounting multilayer printed cables by eliminating interconnections with wire or plating through holes in the layers. Minimize noise emission and voltage drop of the printed power supply cable along its entire length. To ensure minimum values of active and inductive resistances of cables, as well as to reduce their volume and overall parameters. To reduce weight and, accordingly, specific cost, as well as to ensure the possibility of its reliable electrical connection with several electronic units along the entire length of cable, and not only due to its end sections.

Proposed and developed by LLC «RPE «LTU» innovative technical solutions of multisensor modules on flexible commutation boards (Patent of Ukraine for invention of useful model №12321 from 17.02.2021 “Multisensor module on flexible commutation boards”) allow to improve electrical parameters of the module, to reduce its influence on the trajectory and energy of passing particles. Increase module resistance to mechanical impacts and reduce deformations caused by temperature changes. Increase radiation resistance and radiation length of the module, exclude corrosion of welded joints, reduce degradation of electrical characteristics. To increase reliability in operation and to simplify multilayer flexible printed circuit boards mounting technology by excluding wire interconnections or plating through holes in board. Minimize interference emission throughout the module’s area and, therefore, reduce sensor noise. Reduce the volume and size parameters, weight and unit cost of multi-sensor modules.

LLC “Research and production enterprise “LTU” for the first time in Ukraine developed, introduced and implemented in production of new types of laminated materials for flexible and flexible-rigid aluminum-polyimide adhesiveless multilayered printed circuit boards with reduced cost compared to world analogues. Based on these materials, technologies for manufacturing flexible multilayer printed power cables and multisensor modules based on monolithic active pixel sensors (MAPS) and flexible multilayer boards on aluminum foil have been developed and implemented into production. Innovative multisensor pixel detector modules on aluminum foil developed by LLC “Research and Production Enterprise” LTU ” on ultra-modern thin (50 microns) silicon sensors ALPIDE provide record-breaking performance of semiconductor calorimeters for physical experiments. In particular, to ensure the relative radiation length of the modules is not more than 0.1-0.2%X0, spatial resolution is up to 5-10 microns with minimum possible mass and power consumption of modules, as well as a significant reduction in labor intensity of their manufacturing process.

DESCRIPTION OF CAPABILITIES (AVAILABLE SERVICES)

MULTI-SENSOR MODULE ON FLEXIBLE COMMUTATION BOARD

| Module belongs to microelectronic devices both household and special purposes and can be widely used in the production of flat multicrystalline bare detectors on flexible-rigid multilayer carriers, including for particle detection systems and for monitoring the state of elementary particle flows in the Earth’s outer space | Multi-sensor full-aluminum pixel detector module provides high range of performances for modern pixel detector systems: | |

| geometric dimensions, mm | up to 250х50 | |

| radiation length, % X | more than 270,0 | |

| spatial resolution, um | 2,6-2,8 | |

| power consumption, mW/cm2 | up to 120,0 | |

| At minimal possible mass and power consumption of the module. | ||

FLEXIBLE MULTILAYER PRINTED POWER CABLE

| Product refers to development and production of equipment based on microelectronics products both for household and special purposes and can be widely used in the production of particle detection systems, and is intended for the electrical supply of several electronic units or modules. | The multilayer flexible aluminum-polyimide printed power cable minimizes interference emission and voltage drop of printed power cable along its length, minimizes active and inductive cable resistances, as well as reduces dimensional and weight reduction,provides reliable electrical connection to multiple electronic units over length of the cable, not just at the end of the cable. The cable has: | |

| dimensions, mm | up to 1500х40 | |

| thickness of aluminum layers, μm | 30-100 | |

| thickness of polyimide layers, μm | 15-20 | |

| thickness of protective polyimide layer,μm | 40-50 | |

SPECIAL FLEXIBLE AND FLEXIBLE-RIGID ALUMINIUM-POLYIMIDE PRINTED CIRCUIT BOARDS

| Circuits and commutation elements based on aluminum-polyimide adhesiveless dielectrics allow to decrease material budget and working volume of electronic modules with high density of information channels. Flexible and rigid board technologies offer many viable solutions, including promising solutions for creating spatial interconnections. | Technological level of production. Circuits and cables with small traces: | |

| pitch of traces, μm | 45-60 | |

| width of traces, μm | 20-30 | |

| length, mm | 10-50 | |

| number of traces, pc | 128-1024 | |

| Connection cables: | ||

| pitch of traces, μm | 100-200 | |

| width of traces, μm | 40-100 | |

| length, mm | up to 600 | |

| number of traces, pcs | up to 512 | |

PUBLICATIONS

| Article title | |

| 2015 | |

| 1 | The ALICE Collaboration Technical Design Report for the Upgrade of the ALICE Inner Tracking System / B. Abelev, V.N. Borshchov, O.M. Listratenko, M.A. Protsenko, I.T. Tymchuk and the ALICE Collaboration // (CERN-LHCC-2013-024/ALICE-TDR-017) – Journal of Physics G: Nuclear and Particle Physics, Volume 41, Number 8, August 2014, Р. 70 – 71. |

| 2018 | |

| 2 | Innovative microelectronic technologies for high-energy physics experiments / V. M. Borshchov, O. M. Listratenko, M. A. Protsenko et al. // Functional materials. — 2017. — Vol. 24, № 1. — Р. 143-153. |

| 2019 | |

| 3 | New approaches to the creation of high-performance radiation detectors for concentrator solar modules /V.N. Borshchev, O.М. Listratenko, М.А. Protsenko, I.Т. Tymchuk, O.V. Kravchenko, M.I. Slipchenko // Radiotekhnika : All-Ukr. Sci. Interdep. Mag. 2019. №197. P. 123-136. |